“We have invested in the very latest in Orbital Welding machinery to allow production to be 100% efficient and the quality to be of the highest standard.”

The THP project has enabled HLE to invest heavily in pipe fabrication machinery and new staff skills. We have a full compliment of welding procedures that cover any aspect of pipe welding from manual TIG welding through to Machine Orbital Welding.

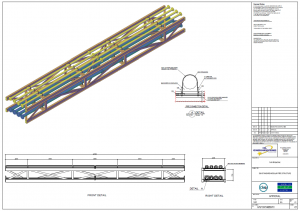

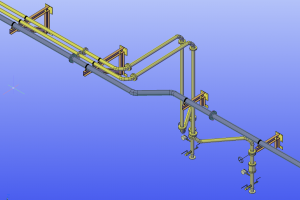

The cross site pipework needs to fully supported by structural steelwork and built in such a way that installation is quick and simple. We have developed a modular system that get enables both pipework and steel work to be installed at the same time. All modules are fully calculated both structurally and from a flow design prospective.

The pipework starts at one end of the site connecting to the coolers with 8 lines. 4 flow and 4 return. All then terminating at different locations as required along their route.

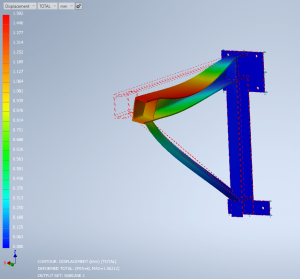

HLE have carried out all detailing and FEA analysis in-house with structural and flow design calculations overseen by our chosen design consultancy partner Waldeck Consulting.

If You Need Any Industrial Solution … We Are Available For You

HL (UK) Holdings Building,

Normanby Road

Scunthorpe

DN15 8QZ

United Kingdom

HL (UK) Holdings Building,

Normanby Road

Scunthorpe

DN15 8QZ

United Kingdom